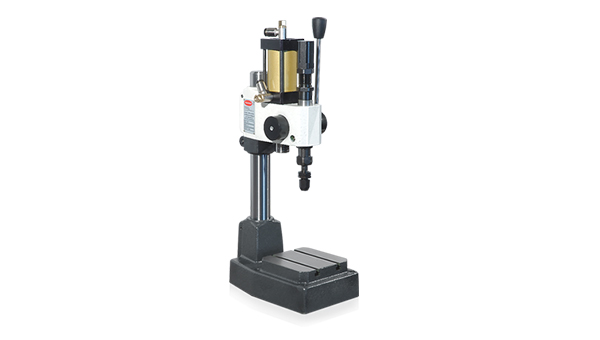

Metal Stamping Machines

A metal stamping machine is a reliable solution for marking standard information quickly and effectively. Designed with a unique impact mechanism, these machines create durable, legible marks on various materials, making them indispensable for industries requiring efficient product identification. At Nichol Industries, we provide advanced metal stamping machines for sale, ensuring precise and consistent results for your operational needs.

Request a sample

Metal Stamping Products

Manual

MB15

- Dimensions: 132x450x210 mm

- Weight: 10kg

- Adjustable power: 0 – 500kg

MB20

- Dimensions: 205x650x309 mm

- Weight: 33kg

- Adjustable power: 0 – 3000kg

M32

- Dimensions: 280x850x443 mm

- Weight: 99kg

- Adjustable power: 0 – 6500kg

MICRO PUNCH

- Dimensions: 16×150 mm

- Weight: 170g

- Adjustable power: 0 – 50kg

Other Applications

MB19

- Dimensions: 138x380x225 mm

- Weight: 14.5kg

- Adjustable power: 0 – 600kg

MB21

- Dimensions: 208x600x355 mm

- Weight: 53kg

- Adjustable power: 0 – 3500kg

MB21VP

- Dimensions: 395x115x130 mm

- Weight: 2kg

- Adjustable power: 0 – 3500kg

IMPACT MECHANISM

- Dimensions: 240 to 690

- Weight: 0.60 to 10.2kg

- Adjustable power: 0 – 6500kg

Learn more about prices and products that suits your needs

What Are Metal Stamping Machines?

Metal stamping machines are ideal for applications where a fast marking of standard information is required.

Metal stamping machines utilise an impact mechanism to apply force for stamping, punching, and staking. This process involves compressing and releasing energy via a spring-loaded section, delivering the force required to mark materials effectively.

Key Features of Metal Stamping Machines

- High-speed marking for efficient operations.

- Durable and repeatable markings.

- Compatibility with various materials and applications.

- Minimal maintenance requirements for cost-effective use.

Our machines are ideal for industries that need rapid, reliable marking solutions without compromising on quality.

The machine creates the force needed for stamping, punching and staking by utilising a unique impact mechanism which clamps the product before building up internal pressure and “firing” into it (compress and release of spring-loaded energy section).

How To Choose The Right Metal Stamping Machine?

Metal (or Impact) stamping is a very popular marking solution among metal stamping manufacturers because of its setup simplicity, repeatability, operational ease, and low maintenance.

It is, however, important to keep in mind that there are multiple variables to consider when choosing the right metal stamping machinery.

Selecting the right metal stamping machine depends on several factors specific to your requirements. To make the best choice, consider the following:

- Materials: Identify the type of material to be stamped, such as steel, aluminium, or brass.

- Stamping Size: Determine the dimensions of the stamp required.

- Number of Lines: Assess the number of text lines and characters per line needed for your marking.

- Volume: Evaluate the production volume—low, medium, or high.

- Post-Marking Processes: Consider any additional processes, such as galvanising or coating, that the markings must endure.

At Nichol Industries, we guide you through these considerations to help you select the most suitable metal stamping machine for sale from our comprehensive range.

Nichol recommends manufacturers consider:

- Materials that be stamped

- Size of the stamping needed

- Number of text lines to be stamped

- Characters per line

- Volume of part marking required (low, medium or high)

- Post marking processes, if any

Applications of Metal Stamping Machines

Metal stamping machines are versatile tools used across a wide range of industries for marking and identification purposes. Common applications include:

- Automotive: Marking components with serial numbers and compliance codes.

- Manufacturing: Labelling parts for assembly and inventory management.

- Aerospace: Identifying aircraft parts with durable and precise markings.

- Industrial Equipment: Adding permanent marks to machinery and tools for tracking and maintenance.

Our machines can also create custom metal stamps, allowing businesses to personalise their markings for branding or operational purposes.

Benefits of Using Metal Stamping Machines

- Efficiency: High-speed stamping reduces production time.

- Durability: Marks are long-lasting and resistant to wear, ensuring reliable identification.

- Versatility: Compatible with various materials and capable of handling complex marking requirements.

- Cost-Effectiveness: Low maintenance needs and durable performance reduce operational costs.

- Precision: Advanced technology ensures clear and consistent markings, improving traceability.

Explore Our Metal Stamping Solutions

At Nichol Industries, we offer a range of metal stamping solutions to suit diverse business needs. Whether you require a machine for high-volume production or intricate custom markings, we have you covered:

- Impact Stamping Machines: Reliable and robust for heavy-duty applications.

- Custom Metal Stamps: Personalised solutions for branding and unique operational requirements.

- Industrial Metal Stamping Machines: Designed for precision and efficiency in demanding environments.

Our team provides expert guidance to ensure you select the best solution for your business.

Why Choose Nichol Industries?

With decades of experience in the marking industry, Nichol Industries is a trusted provider of metal stamping machines for sale. Here’s why businesses choose us:

- Quality Products: Our machines are built to last, delivering consistent and reliable performance.

- Customisation Options: We offer tailored solutions, including custom metal stamps, to meet your specific needs.

- Expert Support: From consultation to after-sales service, our team is dedicated to helping you achieve optimal results.

- Competitive Pricing: Explore cost-effective options without compromising on quality.

Looking for a reliable metal stamping machine? Contact Nichol Industries today to learn more about our products and services. Let us help you find the perfect stamping solution for your business needs.

Frequently Asked Questions

A metal stamping machine is used to create durable and precise markings on various materials. It is ideal for applications requiring rapid marking, such as serial numbers, compliance codes, and product identification.

When choosing a machine, consider factors like material compatibility, stamping size, production volume, and post-marking processes. Nichol Industries can guide you in selecting the most suitable solution for your requirements.

Custom metal stamps allow businesses to personalise their markings for branding or operational purposes. They offer flexibility and ensure that markings align with specific business needs.

Yes, these machines are cost-effective due to their low maintenance requirements and durable performance. They reduce operational costs by ensuring consistent and reliable markings.

Nichol Industries provides high-quality machines designed for precision and efficiency. With expert support and customisation options, we deliver solutions tailored to your business needs.