In today’s environment, a wide range of issues need to be considered as manufacturers look for their competitive edge. Part numbering has emerged as an area where manufacturers can value add as well as providing an opportunity for reducing costs. Often a unique code for each part is required, with batch numbering not providing accurate traceability.

Part numbering, or product identification and traceability as it is sometimes called, has been used for identification for centuries. Artist signatures on paintings and jewellers hallmarks on jewellery are early examples of part numbering. These markings served as excellent branding tools on various pieces and added significantly to their value.

The reasons for part numbering can be categorised in six broad areas.

1 Regulations

Government regulations require part marking for certain industries. The most common government regulated part marking is Vehicle Identification Numbers (VIN) used in the automotive industry. The VIN is used at a number of points during the life of the vehicle. During assembly, the VIN is used to track the product through production and determine the model, or specifications, of the vehicle. Once the vehicle is registered, the VIN provides the unique number for tracking ownership. The VIN also provides a valuable resource for authorities in the identification of stolen vehicles. A paper rubbing of the VIN is still used in a number of countries for ownership record keeping. An engine number is also a regulatory requirement in most countries.

The engine number provides similar benefits to the VIN. Other industries where regulations require part marking include: aerospace, oil and gas, water, pharmaceutical and medical. Part marking is a very important process in industries where it is a regulatory requirement because goods cannot be sold without the required mark.

2 Quality System requirements

Most quality systems require compliance to an identification and traceability clause. ISO9001 is the most popular quality standard. Paragraph 7.5.3 defines the requirement for identification and traceability of products. Part marking is a critical requirement for many quality standards. Consideration needs to be given to the data within the part number and the durability of the mark. Many standards require a part number that is available for the life of the product.

Compliance with the standard cannot be achieved without the correct part marking.

3 Customer demands

More and more customers require part marking on goods supplied. The part marking provides identification of the supplier and the date supplied. This data is used to record quantities supplied with any given shipment and to monitor supplier performance as well as grading of suppliers.

This adds value to the process by ensuring correct delivery quantities are recorded and ensuring the better quality suppliers are being utilised. From a supplier’s point of view, part marking prevents one supplier being held responsible for another’s defects.

4 Warranty Claims

There is a significant cost associated with false warranty claims. False warranty claims occur when a warranty claim is made for goods out of warranty period or when a warranty claim is made for goods made by another manufacturer. Part numbering plays an important role in reducing the cost of these claims. Part marking the product with manufacturers name, date of manufacture and a serial number provides clear and concise details of whether or not the warranty claim is valid. When using compliance plates for this data, many manufacturers are including a ‘voids warranty if removed” statement on the plates. Domestic appliances are the most common product where part marking is used to reduce the cost of false warranty claims.

5 Decoration and Branding

A high quality, well recognised brand is of significant value in today’s marketplace. Part marking is being used. to enhance brand value. Logo’s, model numbers, special features are all marked on products. Imagine an Apple Iphone without the destinctive apple logo. Product branding is used in many industries, even if it is simply to encourage repeat orders.

Decoration of products is also commonly used in a large range of industries.

6 Asset Tracking

Part numbering of assets provides a valuable method of tracking assets, particularly with the addition of 2D codes for electronic reading. The ability to scan assets significantly reduces the frequency of lost assets. The number of the part is scanned into purpose built software that records asset location, responsible person, age, maintenance schedules and depreciation. This can also be used in the stock taking process. This also ensures assets are properly maintained and replaced in a timely manner, reducing down time.

Part numbering, used in conjunction with the appropriate software, is providing large cost savings in tool stores across many industries.

Technology has played a big part in reducing the cost, and increasing the efficiency of the methods of marking.

Traditional part marking was achieved by hand engraving individual numbers, letters or logo’s on products. Later on, a hand made steel stamp was used with a hammer to achieve the same result.

Today a number of methods are available and can be adapted to individual requirements.

Impact stamping presses

Impact stamping presses have been on the market for a long time but remain relevant to certain applications. Impact presses utilise a unique internal mechanism that generates power to push letters into the part. The pushing process eliminates potential bruising sometimes seen with the traditional hand stamp and hammer process.

Impact stamping is the best option for low volume batch numbering applications.

It is not a good option for numbers unique to each part.

Dot Peen

Dot peen marking entered the market in the mid 1980’s. The dot peen is a process whereby a computer controlled pin is pushed into the part to indent a dot. This process continues as the pin moves around an XY table to form dot matrix characters on the part. Early systems, like many computer systems, were large, costly and inflexible. While most systems have reduced in size, some remain oversized and lack capability. The most up to date systems feature small touch screen controllers, the features of a word processing package and the integration capability of a PLC. The marking speed and depth of mark achievable has also significantly increased.

Dot peen systems are fast becoming the most common marking method due to the increased flexibility, capability and reduced cost.

Dot peen is most suitable when a unique number is required to be indented into the part.

Laser

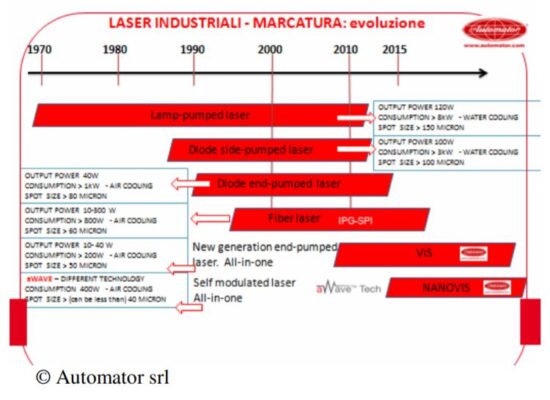

Using a laser for part marking began to evolve in the early 1970’s. Again systems were large, complex, very expensive and high in energy consumption.

Technology changes have reduced the size of the laser markers, increased the capability and reduced the energy consumption:

The above chart shows the evolution of laser marking systems with the up to date systems utilising aWave™(note1) technology to optimise the performance of the laser marking head. Today’s systems are “all in one” eliminating the computer, cooling system and separate controller needed in the older laser markers. Quality of mark has also increased with the reduction in beam “spot size”. Laser systems are the best solution for high speed, high quality applications where marking depth required is not significant. The latest release laser systems are small enough to replace dot peen systems and this may be the trend for the future.

As manufacturer’s face increased competition, increasing costs and increasing customer demand, part marking is one way to add value to your manufacturing process, increase customer satisfaction and give your organisation a competitive edge.

As a result of this, major suppliers within the marking industry are moving from equipment sellers to solution providers with a strong knowledge base and access to a range of equipment. These suppliers will evaluate a customer’s requirements and recommend an outcome that provides real benefit.

1. Awave is a trademark of Automator srl, Milan Italy

About the Author: Adam Nichol CPA has 30 years experience in the marking industry and is part of a network of industry peers from 75 countries

He is currently President, Automator Asia Pacific Pty Ltd and Managing Director, Nichol Industries Pty Ltd He can be contacted at [email protected] with any feedback and questions.